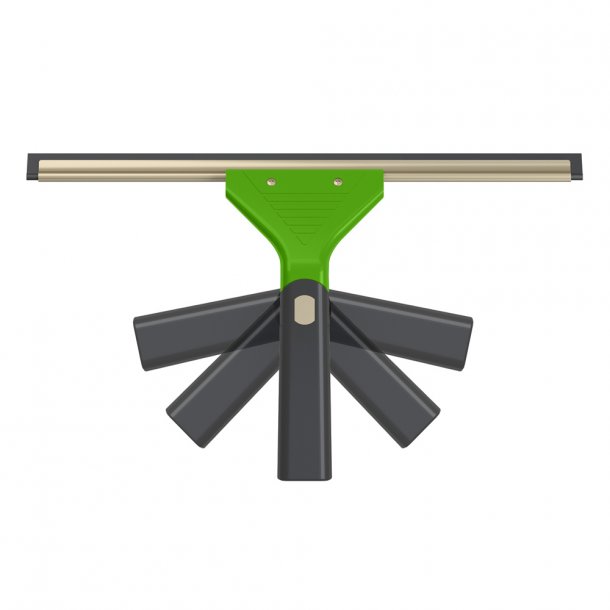

The swivel window squeegee has been specially designed to clean difficult windows, i.e. with tight corners or unusual rounded or convex shapes.

It is necessary when the window cleaner is forced to stand still in a particular po- sition without being able to move backwards or forwards but needs to work at an angle. It is enough to apply a slight pressure to the channel – the same as in the brass version – against the window frame to position the squeegee at the correct working angle, within a 180° range.

The rubber blade is the main component of every squeegee since it is the element that comes into direct contact with glass and dirt. In the vast majority of squeegees available on the market the blade gets deformed when it comes into contact with dirt, which is abrasive, and is exposed to atmospheric agents or is subjected to friction on window frames and under the eaves. This is pre- cisely why TQR (Total Quality Rubber) came about, which makes Pulex rubber the only one on the market used in a total quality squeegee. All our rubber blades guarantee a perfect combination of three requirements – the type and nature of the rubber, the quality of the mix and the cutting edge of the blade.

Our blades are made of genuine vulcanized natural rubber (NR), which is subjected to compres- sion moulding, item by item, and must have consistent and homogeneous chemical and organic features.

We process the raw material to obtain a mix with no impurities that guarantees the vital requisites of perfect molecular dispersion, crosslinking, elasticity, snap, resilience, hardness, resistance to chemical and atmospheric agents, colouring and surface smoothness.

This brings us to namely the perfection and linearity of the blade’s cleaning edge, which depends on the cut made by precision machines and scrupulous quality control.